Product Series

-

-

-

-

Grinding and polishing equipment

-

Molding equipment

The mold clamping pressure, lifting speed, and opening and closing actions can all be controlled and adjusted.

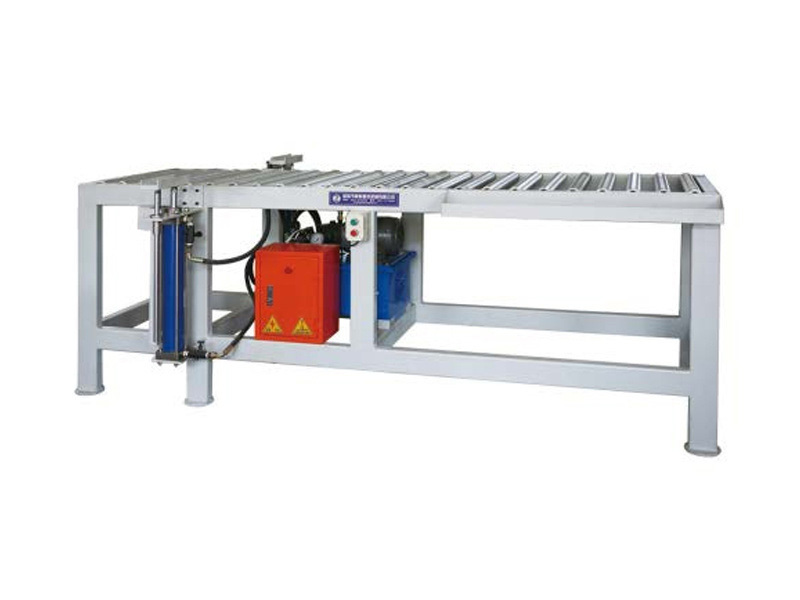

T65-Hydraulic mold opening and closing roller table

This machine uses hydraulic lifting to open the mold after curing, remove the material, clean the mold and refill it.

After the molded product is cured, the circulating water on the cold press table is cooled down through the chiller and cooling tower, so that the mold can be cooled quickly, the production cycle can be shortened, and the work efficiency can be improved.

The motor drives the trolley to move forward and backward, and the hydraulic cylinder drives the load-bearing platform to move up and down, helping the mold to be transferred between the operating table and the hot pressing table.

The heat is transferred to the hot press molding machine platen through the heat transfer oil to heat the product model and complete the curing.

This machine is used to cool down the molded products after the hot pressing molding table is cured.

Quick Quote

We will contact you within 1 business day, please look out for emails with the suffix “service@tonglian.cc”.

*Note: Please be sure to fill in the information accurately, and keep your communication open, we will contact you as soon as possible!