-

-

Prepreg equipment

-

T01-Woven Fabric Dipper

-

T02-Carbon Cloth Laminator TFH-1000

-

T03-Hot Melt Coating Machine TJ1000

-

T04-punching roll laminating machine

-

T05-Automatic large sheet cutting machine

-

T06-Adjustable corner automatic large sheet cutting machine

-

T07-Broach type cloth cutting machine

-

T08-Broach type automatic small sheet cutting machine

-

T09-Automatic corner sheet cutting machine

-

T10-45 degree cutting composite line

Show More -

-

Tube rolling equipment

-

T11-TJG-100 ball screw tube coiling machine

-

T12-SKJG-100 CNC tube rolling machine

-

T13-CNC key type tube winding machine

-

T14-Double Cantilever Ball Screw Tube Rolling Machine

-

T15-Gantry tube coiler

-

T16-Large diameter three-roll tube coiling machine

-

T17-Small tip coiling machine

-

T18-CNC high precision tip coiling machine

Show More -

-

Winding Tape (Winding OPP) Equipment

-

T19-TWC-50 Horizontal CNC Tape Wrapping Machine

-

T20-TWC36-B Long Roller Horizontal CNC Tape Wrapping Machine

-

T21-TWC36-II long idler double purpose belt winding machine

-

T22-TWC36-C Lifting Roller Horizontal CNC Tape Wrapping Machine

-

T23-TWC36-D Top Horizontal CNC Tape Wrapping Machine

-

T24-TWC36-E double-shaft horizontal wrapping machine

-

T25-Weight Type Large Diameter Top Horizontal Tape Wrapping Machine

-

T26-LC-50B precision vertical winding machine

-

T27-TCWC-50C automatic centering horizontal vertical winding machine

Show More -

-

Curing molding equipment

-

T28-Single fan compound curing furnace

-

T29- GH-2000 double fan compound curing furnace

-

T30-Horizontal curing oven

-

T31-Horizontal tunnel furnace

Show More -

-

Demoulding equipment

-

T32-TX-800 core removal machine

-

T33-Moduleholder removable coring machine

-

T34-CNC servo coring machine

-

T35-large diameter core stripping machine

Show More -

-

Cut-off equipment

-

T36-QD-1600 manual cutting machine

-

T37-TQD-2000 precision semi-automatic cutting machine

-

T38-CNC precision semi-automatic cutting machine

-

T39-ZDQG-36A automatic pipe cutting machine

-

T40-Automatic double-head cutting machine

-

T41-CNC large diameter grinding and cutting machine

-

T42-CNC double-head precision pipe cutting machine

Show More -

-

Off opp belt equipment

-

T43-Single-slot Bopp stripper

-

T44-Multi-slot Bopp stripper

-

T45-diameter pipe stripping Bopp belt machine

Show More -

-

Grinding and polishing equipment

-

T46-SM-50 water mill

-

T47-Inflatable Wheel Soft Grinding Machine

-

T48-LYM-50 semi-automatic grinding machine

-

T49-LRM-50 semi-automatic (soft) grinding machine

-

T50-Single automatic grinding machine

-

T51-Two-machine automatic grinding machine

-

T52-JM-50A Refiner

-

T53-MT1040A Cindless Grinder

-

T54-SMT1040A CNC Cindless Grinder

Show More -

-

Painting equipment

-

T55-QY-II pneumatic marking machine

-

T56-Linear marking machine

-

T57-Horizontal CNC Spraying Machine

-

T58-Vertical CNC Spraying Machine

-

T59-Automatic paint drawing machine

-

T60-Single-sided water curtain spraying cabinet

-

T61-Double-sided water curtain spraying cabinet

-

T62-Stainless steel double-sided spraying cabinet

Show More -

-

Molding equipment

-

T63-TRY-A hot press forming table

-

T64-TLY-A cold pressing table

-

T65-Hydraulic mold opening and closing roller table

-

T66-Hydraulic pump station

-

T67-Hydraulic Lift

-

T68-Chiller, Cooling Tower

-

T69-Mold temperature machine

Show More -

-

Other auxiliary equipment

-

T70-CS-36 automatic threading machine

-

T71-Slot Cutter

-

T72-Trimper

-

T73-Mold Cleaning Machine

-

T74-Automatic Mold Cleaning Machine

-

T75-Flat-type single-sided cloth pressing machine

-

T76-Flat-type double-sided cloth pressing machine

-

T77-Automatic Circulating Filter Tank

-

T78-Ultrasonic cleaning machine

Show More -

-

Fishing rod testing equipment

Show More

-

Share To

T21-TWC36-II long idler double purpose horizontal winding machine

View Similar Products

Tag List

- Product Description

- Function introduction

-

Main technical parameters

Diameter of winding rod: φ1 ~ φ36mm, supported by long idler

Roller length: 2600mm, winding rod length 2400mm (roller and winding belt length can be customized)

Roller structure: both ends of the column support, upper and lower hand wheel lifting,

Left and right movable, double pneumatic lifting roller support in the middle, stable rotation

Working mode: BOPP belt, carbon belt, double-purpose winding belt, working mode: BOPP belt, carbon belt, double-purpose winding belt, and has the function of carbon belt film collection

Control mode: touch screen, PLC constant tension, tension decreasing,

Segment tension, automatic belt distance control

Tension setting range: 1~10kg, control accuracy 0.1kg

Sliding plate: servo motor drive, synchronous belt drive (optional ball screw drive)

Guide belt plate angle mode: servo motor drive, reducer drive, numerical control angle, angle range 45

Working ability: 600~1000 sections/shift

Power: motor power 2.9KW

Power supply: 380V/50Hz, three-phase four-wire ground wire

Gas source: 0.4 ~ 0.6MPa

Dimensions: 4400*1000*1380mm

-

Product introduction

This machine is used for winding BOPP tape and carbon tape on the mold surface, and the winding tape spacing is uniform and stable.

Functional features

① The 35mm diameter steel long roller system supports the slender mold core throughout the whole process, which not only ensures the stability of the core mold during rotation, but also ensures the safety of operation. The brackets at both ends of the long roller are raised and lowered by handwheel rotation, and there are 2 sets of pneumatic support rollers in the middle of the roller for pneumatic lifting support;

② The elastic chuck is used to clamp the mold core, which ensures the minimum diameter jump of the mold core, thereby ensuring the stability of the machine operation to the greatest extent;

③ The slide moves left and right, driven by a ball screw and a servo motor, and runs smoothly. It can run at a constant speed or decelerate at a uniform speed according to a percentage;

④ The tension control system adopts touch screen intelligent control, which can be either constant tension control or segmented tension control;

⑤ The guide plate is driven by a servo motor and swings left and right.

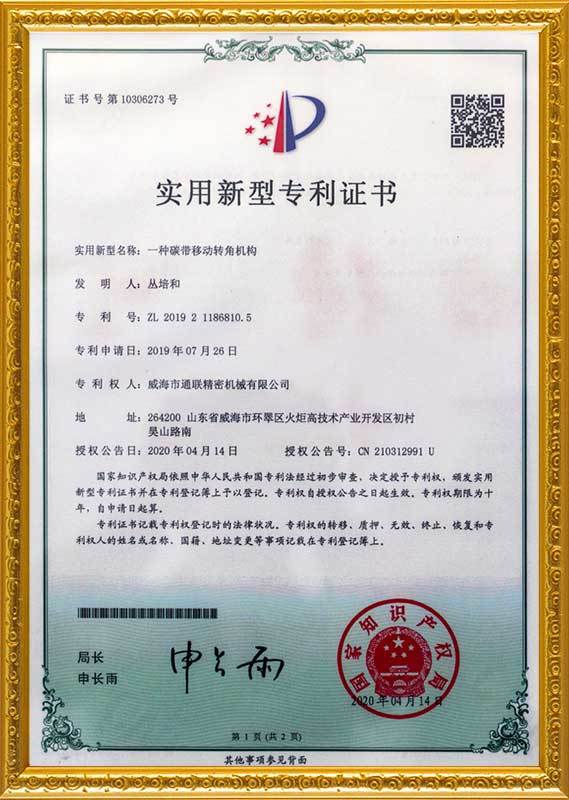

Strength Certification

The company has strong technical research and development strength, advanced mechanical processing equipment, and a number of invention patents and new utility patents. Specialized in manufacturing glass fiber, carbon fiber dip cloth as raw materials, rolled tube forming equipment, molding equipment, winding equipment, solvent-based woven fabric prepreg machine, hot melt carbon fiber prepreg equipment and other various peripheral supporting equipment.

Service

Installation and commissioning

We will send technicians to install and debug the equipment and train personnel to operate free of charge.

Warranty Service

During the warranty period (one year), due to the damage caused by the quality of the equipment (except for improper operation and maintenance and normal wear and tear of wearing parts), we provide completely free service. (Including labor costs, spare parts and other related ancillary costs)

Follow-up services

We provide customers with lifelong maintenance services, outside the warranty period, if you have a request for our door-to-door service, we will be timely door-to-door in response to the appointment, we will charge a reasonable labor hourly fee, spare parts cost and related ancillary costs.

Inspection Services

We will organize after-sales service personnel from time to time, in the case that you do not require door-to-door equipment overhaul and maintenance. When you need to replace the spare parts, we will only charge the cost of spare parts, do not charge the cost of labor and other related auxiliary costs.

T21-TWC36-II long idler double purpose horizontal winding machine

View Similar Products

Tag List

Product Inquiry

Note: Please leave your cell phone and email address, our professional staff will contact you as soon as possible!

Tel:

Email:

Tonglian Precision Machinery can be customized according to customer demand for a variety of glass fiber and carbon fiber composite products peripheral equipment, factory direct sales, quality assurance, after-sales no worries!

ZhenHua Packing Machinery

Factory Switchboard:0086-631-5710888

Emai l: sales002@tonglian.cc

Address:No. 15, Haoshan Road, Chucun Industrial New Zone, Gao District, Weihai City, Shandong Province

ZhenHua Packing Machinery

-

-

-

-

-

Grinding and polishing equipment

-

-

Product Inquiry

Quick Quote

We will contact you within 1 business day, please look out for emails with the suffix “service@tonglian.cc”.

*Note: Please be sure to fill in the information accurately, and keep your communication open, we will contact you as soon as possible!